Types of Corrugated Boxes :

Mailer boxes are one-piece, die-cut boxes that are assembled without tape or glue. Mailer boxes are very strong and will withstand a rigorous shipment process. Engineering of these boxes includes double-layer protection on the bottom and sides. These custom boxes are normally available in two popular styles–With a tuck-in top or with a locking cover.

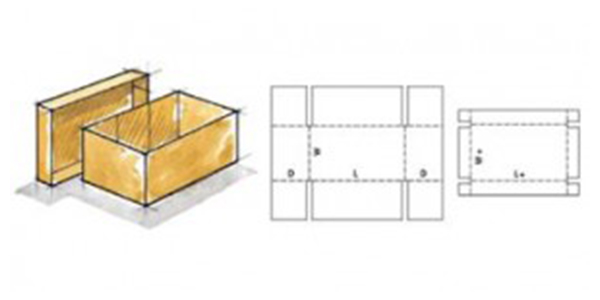

Bin boxes are one-piece, die-cut boxes that can be assembled with or without tape or glue. They are often called shelf boxes used for storing or featuring small items. These long, narrow boxes can significantly increase storage space. Bin boxes have an open top to allow you to see and reach inside. Available in multiple widths and lengths.

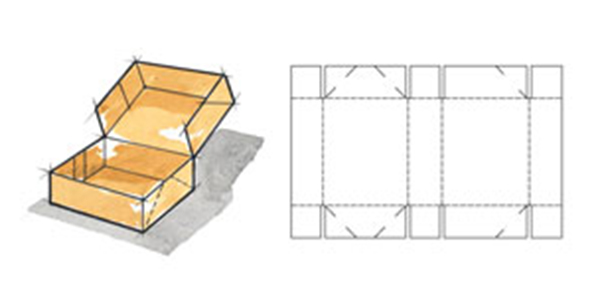

Slide boxes consist of several pieces (liners/sleeves) that slide into each other. They are of the most innovative types of corrugated boxes and include a sleeve used for sliding in multiple directions This group also includes outside sleeves for other cases.

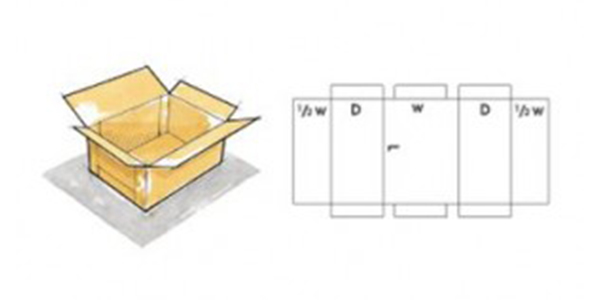

With the help of Computer Aided Design (CAD) programs and top of the line die-cutting machinery, Varun Packaging can make just about any corrugated box style. We are a custom, one-stop shop for all of your product packaging needs. After designing the boxes, the manufacturing process begins by creating the corrugated board needed. The machines we use to make different types of corrugated boxes often occupy several yards.